This procedure contains the minimum requirements to protect our employee s from injury caused by the unexpected energization start up or release.

Lock out tag out procedure for forklifts.

Osha s lockout tagout fact sheet describes the practices and procedures necessary to disable machinery or equipment to prevent hazardous energy release.

Forklift lockout tagout procedures.

Its purpose is to ensure forklifts and other dangerous pieces of equipment are shut down and can t be restarted until they re once again safe to operate.

This lockout tag out procedure is for equipment blocking when equipment is elevated from the surface to allow maintenance to be performed.

The authorized employee shall know the type and magnitude of energy that the machine or equipment utilizes and shall understand the hazards thereof.

Lockout tagout procedural guide rich paul industries 29 cfr 1910 147 ansi z244 1 2003 nashville tennessee 2 reference.

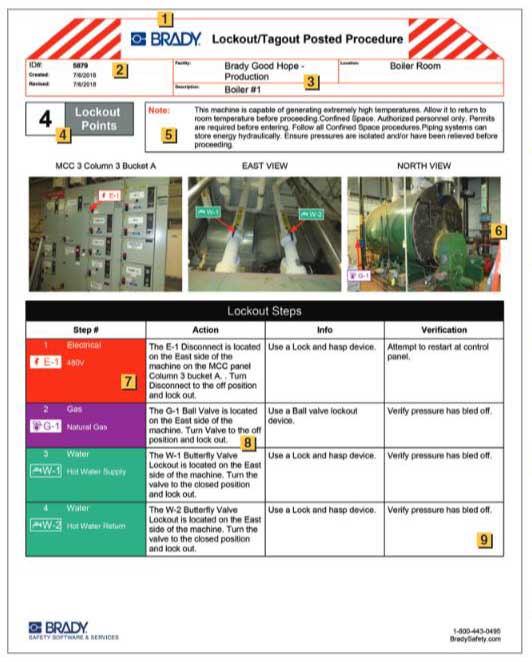

Purpose this procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment.

The next step of the lockout tagout process or procedure is to isolate the machine and or the equipment from any source of energy.

Nissan fork lift i.

Notify all affected employees that a lockout or tagout system is going to be utilized and the reason for its.

Lockout tagout loto is a lock and tag safety procedure used in industrial and research and development r d settings.

Forklift safety lockout tag out procedure.

An effective lockout tagout program should include the following eight steps.

Lockout procedure lockout procedure for name of company for single procedure or identification of equipment if multiple procedures are used.

Next determine the correct procedure for shutting down and restarting the equipment.

A lockout tagout loto procedure is a safety system used to prevent accidental or unauthorized access to electrical power sources that are undergoing maintenance or other work.

Detailed procedures for equipment begin by making sure you ve identified the equipment correctly and accurately including its specific location.

It s fair to say that this entire six step process takes its name from this step.

This may determine any number of items such as the turning off the power at a breaker or shutting a valve.

5 2 sequence of lockout or tagout system procedure notify affected employees that a lock out or tag out system is going to be utilized and the reason.